Stamped Concrete

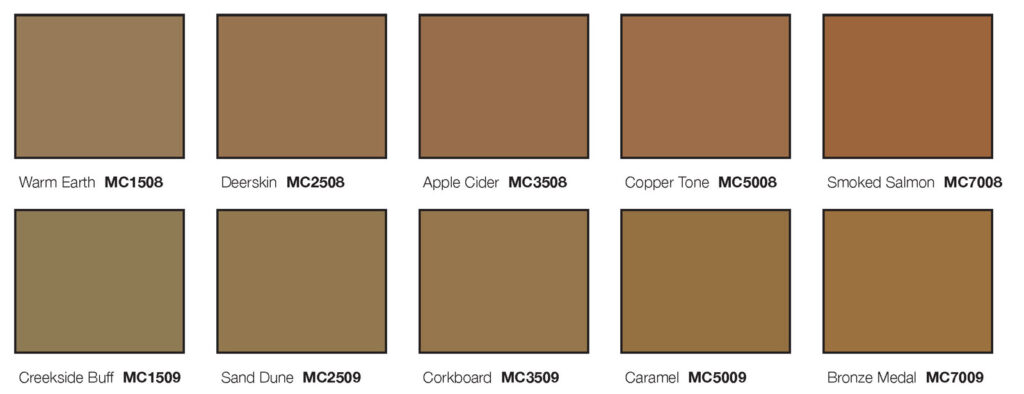

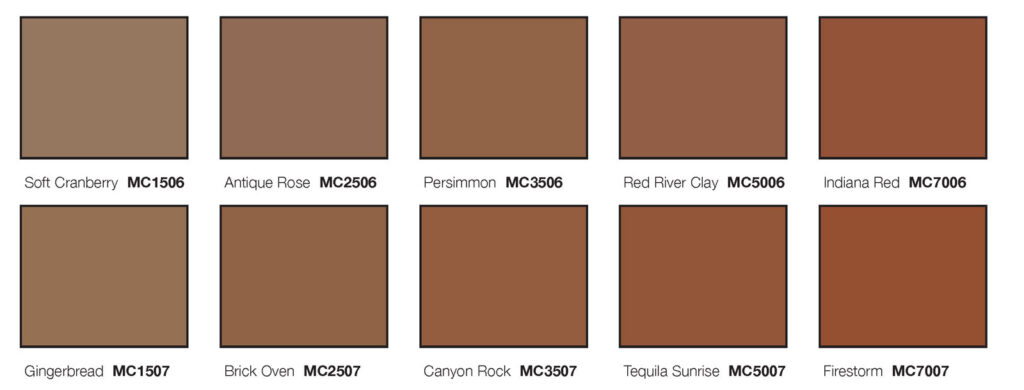

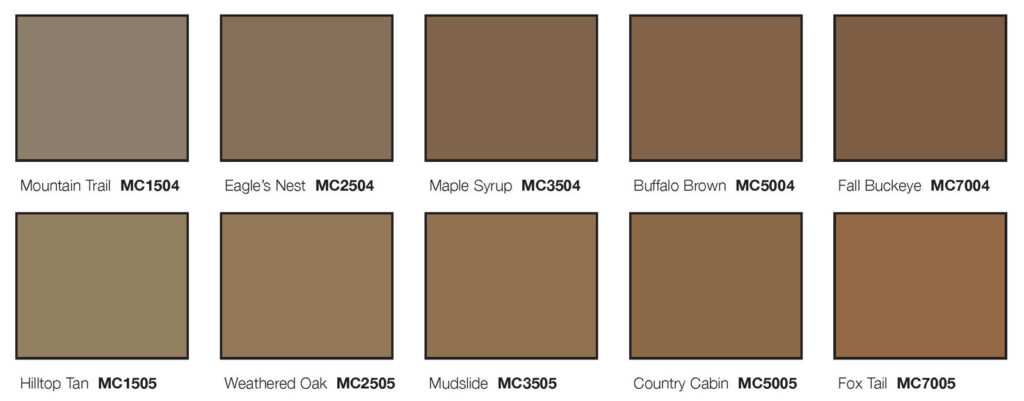

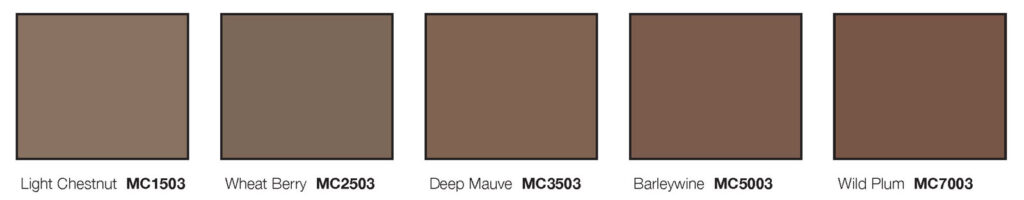

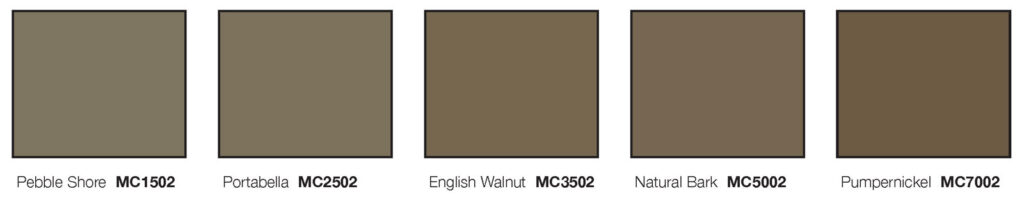

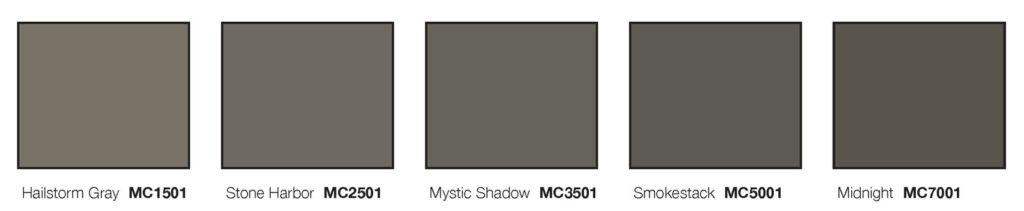

Stamped concrete, also known as textured or imprinted concrete, is a versatile and durable paving option that beautifully mimics natural materials like slate, flagstone, brick, and wood. Its wide array of patterns and colors makes it a popular choice for enhancing patios, pool decks, driveways, and more. This involves staining or coloring the concrete before stamping, which highlights the detailed textures and adds depth to the finish.

Affordable and low maintenance, stamped concrete services is an ideal solution for those looking to upgrade any space without the high cost and upkeep of natural materials. At Eco Concrete Company, we take pride in our stamped concrete finishes that combine curb appeal with eco-friendliness, aligning with our commitment to sustainability and customer satisfaction.